From light and long-lasting materials to perfectly drafted beverages, Aalberts is where technology matters and real progress can be made. Aalberts plays a crucial role in industrial niches where longevity matters. That’s why we are in it for the long haul.

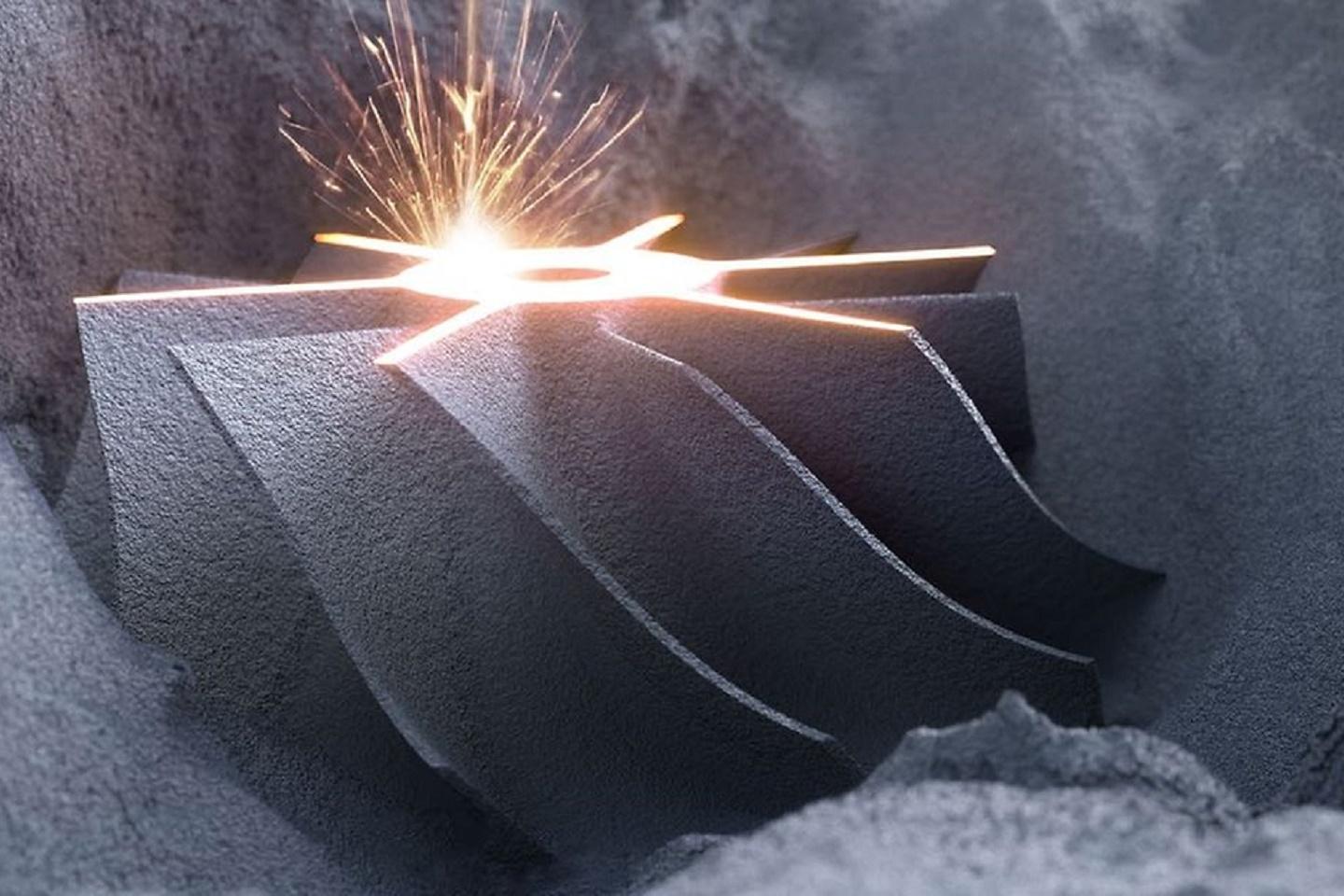

Aalberts surface technologies improves material characteristics for regional and global industrial key accounts. We are specialised in surface treatments, heat treatments, brazing, additive manufacturing and post processing.

Our footprint and strong entrepreneurial culture enables us do business with customers who expect the same technology, process quality and service in different locations of the world. We own every moment when things stop working or when things need to work according to a plan, even when that plan is not fully written.